Ngokuthandwa okwandayo kwamakhanda okusika amandla aphezulu, sithole ukuthi kunezimo eziningi zokuqhuma kwamalensi okuvikela. Isizathu sibangelwa kakhulu ukungcoliswa kwelensi. Lapho amandla enyuswa abe ngaphezu kwama-watts angu-10,000, lapho ukungcola kothuli kwenzeka ku-lens, futhi indawo evuthayo ayimiswa ngesikhathi, amandla adonswayo ayanda ngokushesha, futhi kulula ukuqhuma. Ukuqhuma kwelensi kuzodala inkinga enkulu yokwehluleka ekhanda lokusika. Ngakho-ke namuhla sizokhuluma ngezinyathelo ezingavimbela ngokuphumelelayo i-lens yokuzivikela ekuqhumeni.

Vikela izindawo ezishile namalensi aqhekekile esibukweni

Ukusika igesi

Mayelana nokuhlolwa kwepayipi:

Ukuhlolwa kwendlela yegesi kuhlukaniswe izingxenye ezimbili, enye isuka ethangini legesi ukuya endaweni yokuphuma kwegesi yepayipi legesi, kanti enye isuka endaweni yokukhipha igesi yepayipi legesi ukuya echwebeni lokuxhuma igesi lokusika lekhanda lokusika.

Indawo yokuhlola1.Ukumboza i-tracheal outlet ngendwangu emhlophe ehlanzekile, i-ventilate imizuzu engu-5-10, hlola isimo sendwangu emhlophe, sebenzisa i-lens ehlanzekile yokuzivikela noma ingilazi, uyibeke endaweni yokuphuma ku-tracheal, i-ventilate ngokucindezela okuphansi (i-5-6 bar) imizuzu engu-5-10, futhi uhlole ukuthi i-lens yokuvikela ikhona Kukhona amanzi namafutha.

Indawo yokuhlola2.Mboza i-tracheal outlet ngendwangu emhlophe ehlanzekile, i-ventilate imizuzu engu-5-10, hlola isimo sendwangu emhlophe, sebenzisa i-lens ehlanzekile yokuvikela noma ingilazi, uyibeke endaweni yokuphuma ku-tracheal, futhi i-ventilate ekucindezelweni okuphansi (i-5-6 bar) imizuzu engu-5-10 (khipha 20s; yeka) i-lens engu-10 namafutha), hlola ukuthi kukhona yini i-lens yokuzivikela kanye nowoyela; ngabe kukhona isando somoya.

Qaphela:Zonke izimbobo zokuxhuma kuqhoqhoqho kufanele zisebenzise izimbobo zamapayipi emikhono yekhadi ngangokunokwenzeka, zingasebenzisi izimbobo zokuxhuma ngokushesha ngangokunokwenzeka, futhi gwema ukusebenzisa izimbobo ezingu-90° ngangokunokwenzeka. Zama ukugwema ukusetshenziswa kwetheyiphu yezinto eziluhlaza noma iglue yentambo, ukuze ungabangeli ukuthi itheyiphu yezinto ezingavuthiwe iphule noma ifake udoti weglue endleleni yomoya, okubangela ukungcoliswa kwendlela yomoya ukuvimba i-valve elinganiselwe noma ukusika ikhanda, okuholela ekusikeni okungazinzile noma ngisho nokusika i-lens yekhanda eliqhumayo. Kunconywa ukuthi amakhasimende afake isihlungi esinengcindezi ephezulu nesinemba kakhulu (1μm) endaweni yokuhlola engu-1.

Ukuhlolwa kwe-pneumatic: ungakhiphi ukukhanya, sebenzisa yonke inqubo yokubhoboza nokusika ngokugijima okungenalutho, nokuthi isibuko sokuzivikela sihlanzekile yini.

B.Izidingo zegesi:

Ukusika ukuhlanzeka kwegesi:

| Igesi | Ubumsulwa |

| Umoya-mpilo | 99.95% |

| I-nitrogen | 99.999% |

| Umoya ocindezelwe | Awekho amafutha namanzi |

Qaphela:

Ukusika igesi, igesi yokusika ehlanzekile neyomile kuphela evunyelwe. Ukucindezela okukhulu kwekhanda le-laser ngamabha angama-25 (2.5 MPa). Ikhwalithi yegesi ihlangabezana nezidingo ze-ISO 8573-1:2010; izinhlayiya eziqinile-isigaba 2, isigaba samanzi 4, isigaba sikawoyela 3

| Ibanga | Izinhlayiya eziqinile (uthuli olusele) | Amanzi(Pressure dew point) (℃) | Amafutha (Umusi/Inkungu) (mg/m3) | |

| Ukuminyana okukhulu (mg/m3) | Usayizi omkhulu (μm) | |||

| 1 | 0.1 | 0.1 | -70 | 0.01 |

| 2 | 1 | 1 | -40 | 0.1 |

| 3 | 5 | 5 | -20 | 1 |

| 4 | 8 | 15 | +3 | 5 |

| 5 | 10 | 40 | +7 | 25 |

| 6 | - | - | +10 | - |

C.Izidingo zepayipi lokufaka igesi lokusika:

Ukuvuthela kwangaphambili: ngaphambi kokubhoboza (cishe ama-2s), umoya ukhishwa kusengaphambili, futhi i-valve yokulingana ixhunyiwe noma impendulo yephinikhodi yesi-6 yebhodi ye-IO ixhunyiwe. Ngemuva kokuqapha kwe-PLC ukuthi ukucindezela komoya okusika kufinyelela inani elibekiwe, ukukhishwa kokukhanya kanye nenqubo yokubhoboza kuzokwenziwa. Qhubeka uphephetha. Ngemuva kokuthi ukubhoboza sekuqediwe, umoya uzoqhubeka nokuphuma futhi wehlele endaweni yokulandela yokusika. Phakathi nale nqubo, umoya ngeke ume. Ikhasimende lingashintsha umfutho womoya ukusuka kumfutho womoya ohlabayo uye kumfutho womoya wokusika. Shintshela kumfutho womoya wokubhoboza ngesikhathi sokunyakaza kokungenzi lutho, futhi ugcine igesi ivaliwe, uye endaweni elandelayo yokubhoboza; ngemuva kokuqedwa kokusika, igesi ngeke ime futhi iphakamise, futhi igesi izoyeka ngemva kokuba endaweni ngokulibaziseka kwe-2-3s.

Ukuxhumana kwesignali ye-alamu

A.Ukuxhumeka kwe-alamu ye-PLC

Ngesikhathi sokusebenza kwemishini, kuyadingeka ukuhlola ukuthi uxhumano lwesignali ye-alamu lulungile yini

- Isixhumi esibonakalayo se-PLC siqale sihlole ukubaluleka kwe-alamu (okwesibili kuphela ekumisweni kwezimo eziphuthumayo) kanye nezilungiselelo zesenzo sokulandelela ngemva kwe-alamu (ukumisa ukukhanya, ukumisa isenzo).

- Akukho ukuhlolwa kokukhanya: khipha i-drower yesibuko esingaphansi esivikelayo kancane, i-alamu ye-LED4 iyavela, kungakhathaliseki ukuthi i-PLC inokufaka i-alamu nezenzo ezilandelayo, noma ngabe i-laser izonqamula isignali ye-LaserON noma yehlise i-voltage ephezulu ukuze imise i-laser.

- Ukuhlola okukhipha ukukhanya: Khipha isignali ye-alamu yephinikhodi yesi-9 yebhodi ye-IO eluhlaza, nokuthi i-PLC inolwazi lwe-alamu yini, hlola ukuthi ingabe i-laser izokwehlisa ugesi ophezulu futhi imise ukukhipha ukukhanya.

Uma i-OEM ithole isignali ye-alamu, okubalulekile kungokwesibili kuphela endaweni yokumisa izimo eziphuthumayo (isiteshi sokudlulisa ngokushesha), isignali ye-PLC iphendula ngokushesha, futhi ukukhanya kungamiswa ngesikhathi, nezinye izizathu zingabhekwa. Amanye amakhasimende asebenzisa isistimu ye-Baichu futhi awakayitholi isignali ye-alamu. Isixhumi esibonakalayo se-alamu sidinga ukuhlelwa ngokwezifiso bese usetha isenzo sokulandelela (ukumisa ukukhanya, ukumisa isenzo).

Ngokwesibonelo:

Izilungiselelo ze-alamu yesistimu ye-Cypcut

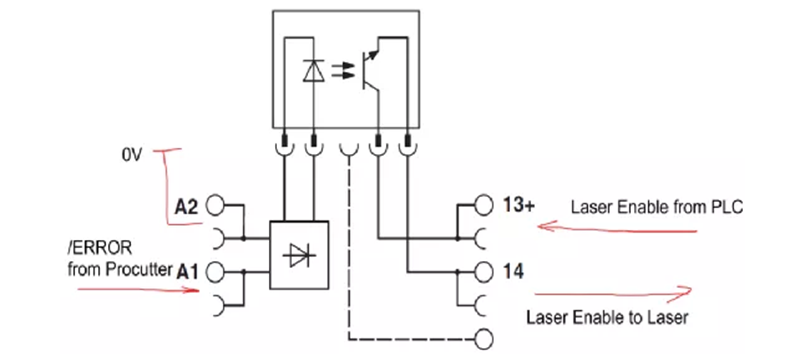

B.Uxhumano lukagesi lwe-Optocoupler

Uma i-PLC ingasisebenzisi isiteshi sokudlulisa ngokushesha, kukhona elinye ithuba lokuthi i-laser ingacishwa ngesikhathi esifushane. Isignali ye-alamu yekhanda elisikayo ixhunywe ngokuqondile ku-optocoupler relay ukuze kulawulwe isignali ye-LaserON (ngokwethiyori, ukuvala ukuphepha kwe-laser kungalawulwa), futhi ukukhanya kunqanyulwe ngokuqondile (i-laser enable nayo isethelwe phansi -> ivaliwe i-laser). Kodwa-ke, kuyadingeka ukuxhuma isignali ye-alamu ye-Pin9 ku-PLC ngokuhambisana, ngaphandle kwalokho ama-alamu ekhanda lokusika, futhi ikhasimende alazi ukuthi kungani, kodwa i-laser iyama ngokuzumayo.

Ukuxhunywa kwezinto zikagesi ezihlanganisiwe ze-opto (i-alarm signal-opto-coupled electrical appliances-laser)

Ngokuqondene ne-gradient yezinga lokushisa, lokhu kudinga ukuhlolwa futhi kusethwe yi-OEM ngokuya ngesimo sangempela sokusika. Iphinikhodi yesi-6 yebhodi ye-IO ishintshashintsha ekukhipheni inani lokuqapha izinga lokushisa lesibuko esivikelayo (0-20mA), futhi izinga lokushisa elihambisanayo lingu-0-100 degrees. Uma i-OEM ifuna ukukwenza, ingakwenza.

Sebenzisa amalensi okuvikela asekuqaleni

Ukusetshenziswa kwamalensi okuvikela angewona awokuqala kungabangela izinkinga eziningi, ikakhulukazi ekhanda lokusika i-10,000-watt.

I-1.I-lens ye-lens engalungile noma izinto ezingalungile zingabangela kalula izinga lokushisa le-lens ukuthi likhuphuke ngokushesha kakhulu noma i-nozzle ishise, futhi ukusika akuzinzile. Ezimweni ezimbi kakhulu, i-lens ingase iqhume;

I-2.Ukuqina okunganele noma iphutha kusayizi onqenqemeni kuzodala ukuvuza komoya (i-alamu yokucindezela komoya emgodini), kungcolise i-lens evikelayo kumojula yokugxila, okuholela ekusikeni okungazinzile, ukusika okungangeneki, nokungcola okungathi sína kwelensi yokugxila;

3.Ukuhlanzeka kwelensi entsha akwanele, kubangela ukushiswa njalo kwelensi, ukungcoliswa kwelensi yokuzivikela kumojula yokugxila, nokuqhuma kwelensi okungathi sína.

Isikhathi sokuthumela: Aug-25-2021